Catheter Processing Capabilities

Whether it’s a “build to print” catheter or working off of a napkin sketch, we have the in-house capabilities necessary to deliver components and finished assemblies on a lightning fast timeline and within your budget.

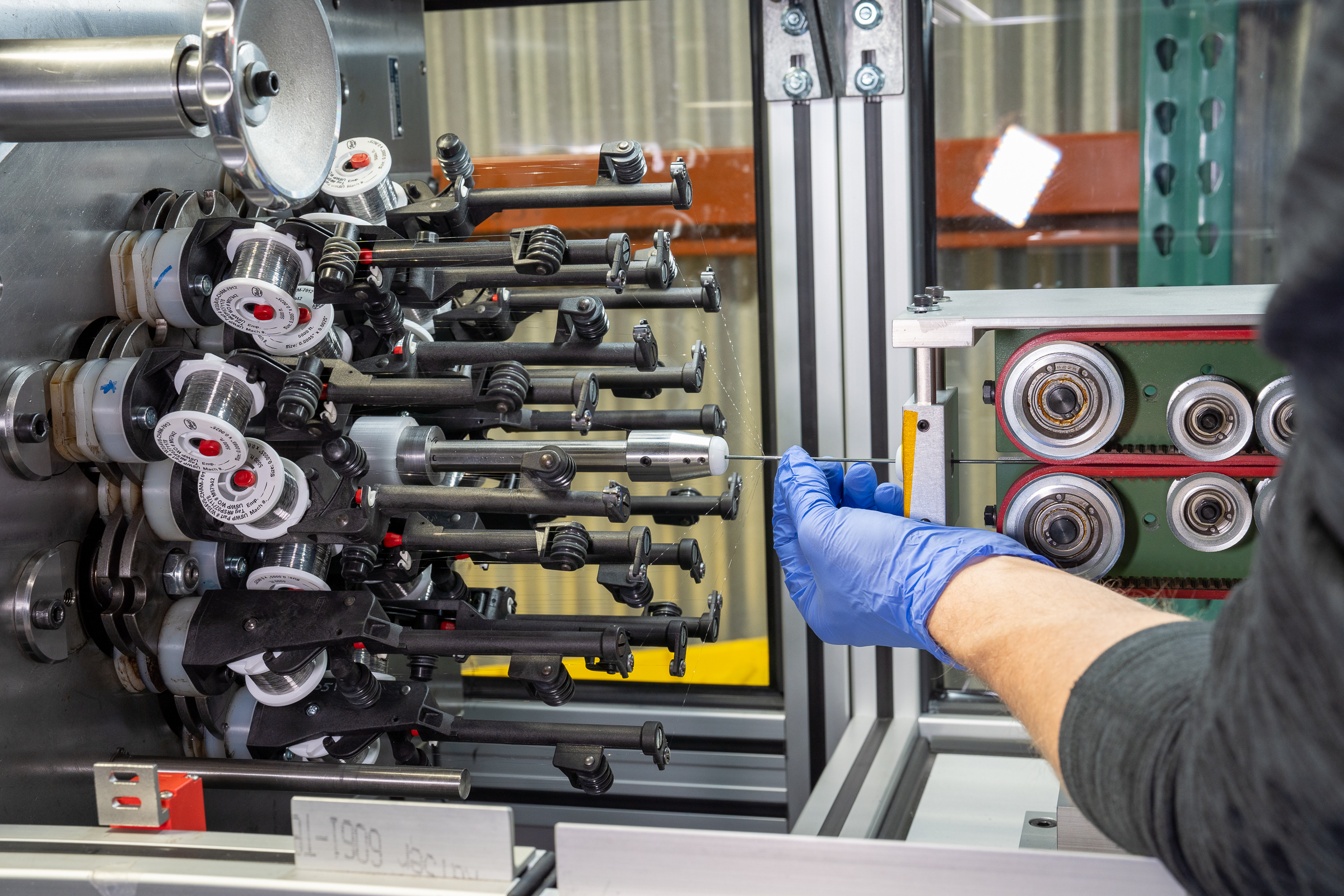

Braiding

We offer fine wire braid patterns used ubiquitously in medical catheter shafts. Braid patterns and configurations come in many shapes and sizes. We can help you choose the right one for your application.

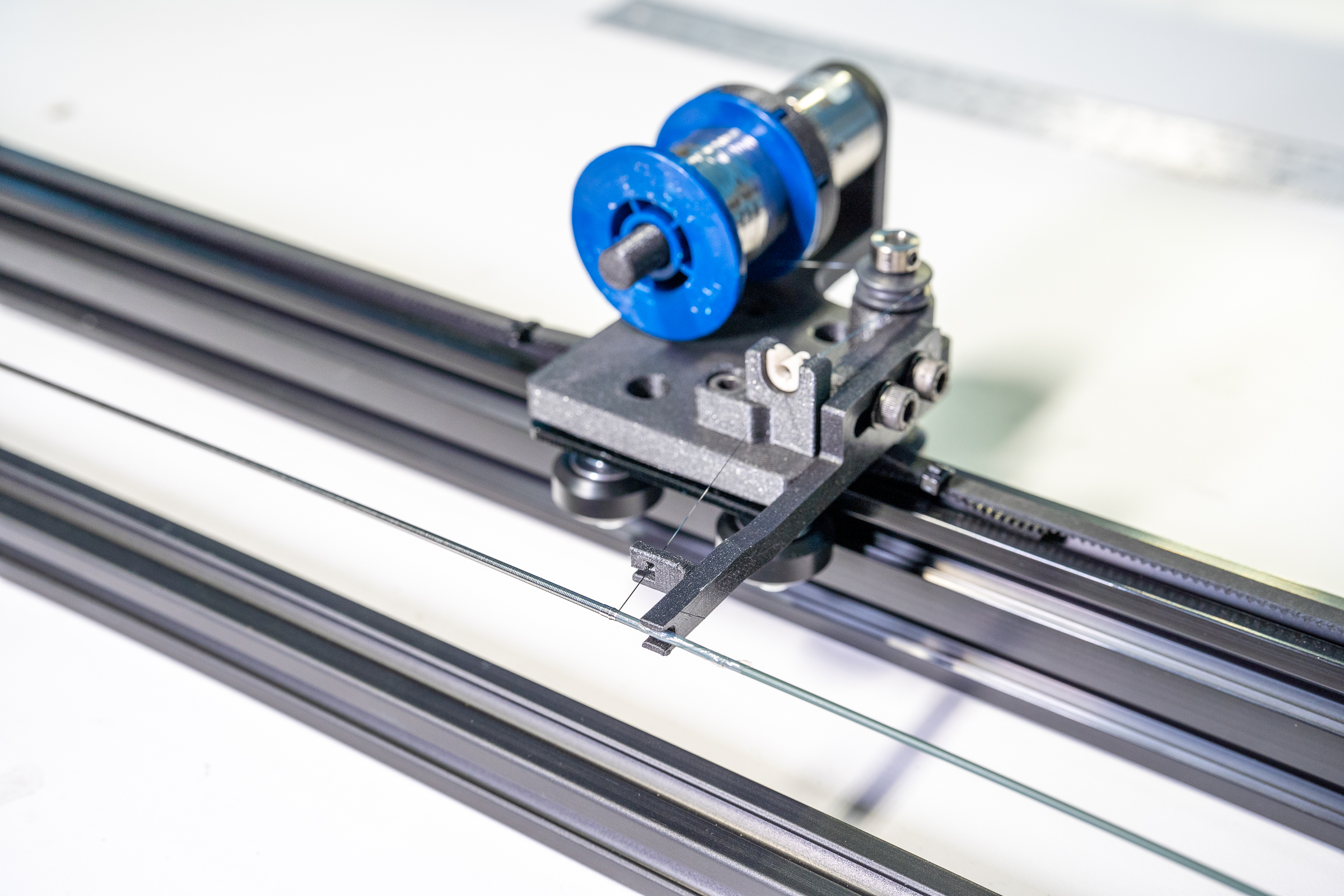

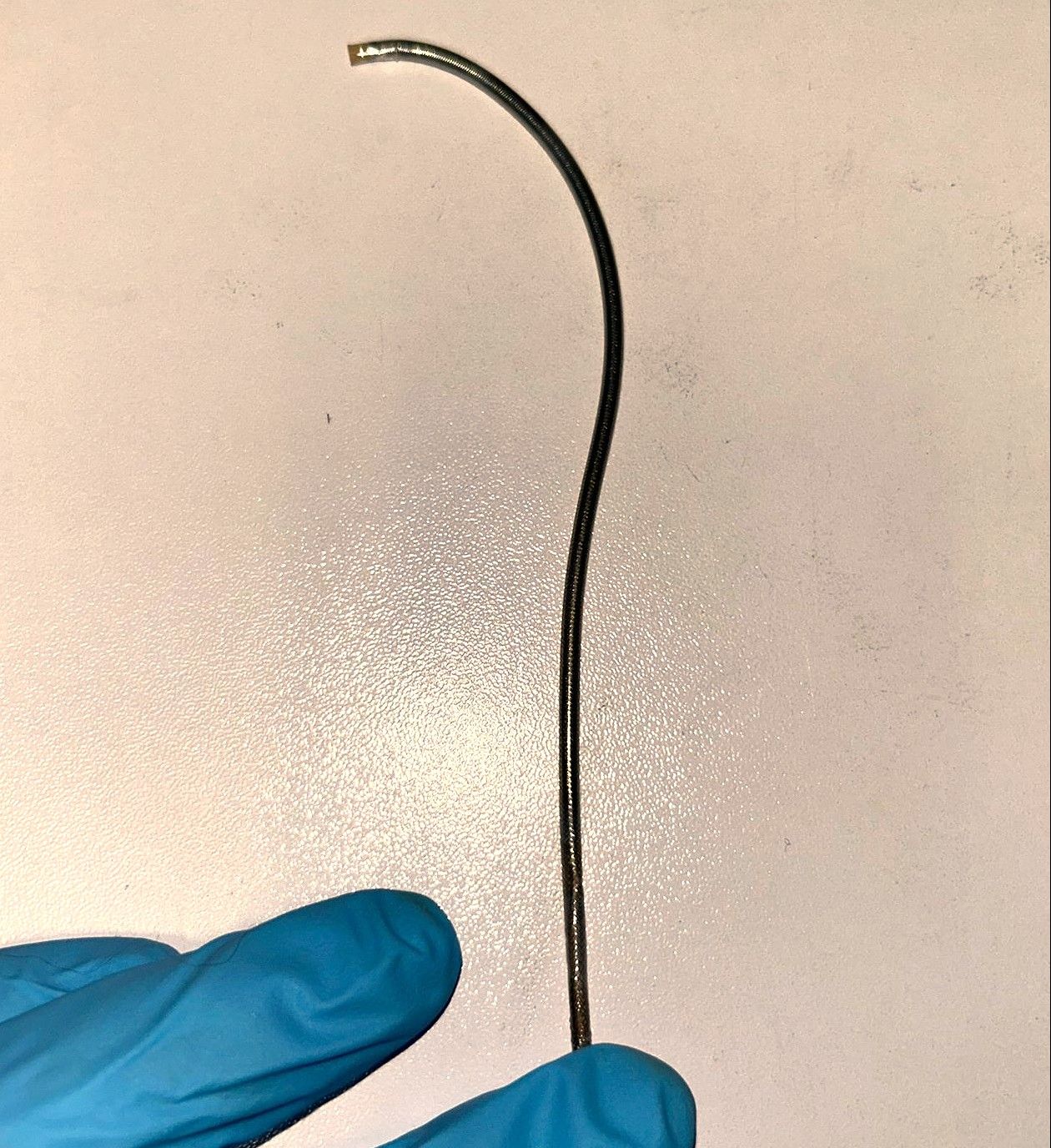

Coil Winding

Coiling offers more flexibility and trackability over a guide wire, while offering less tensile, compressive, and torsional stability of the shaft.

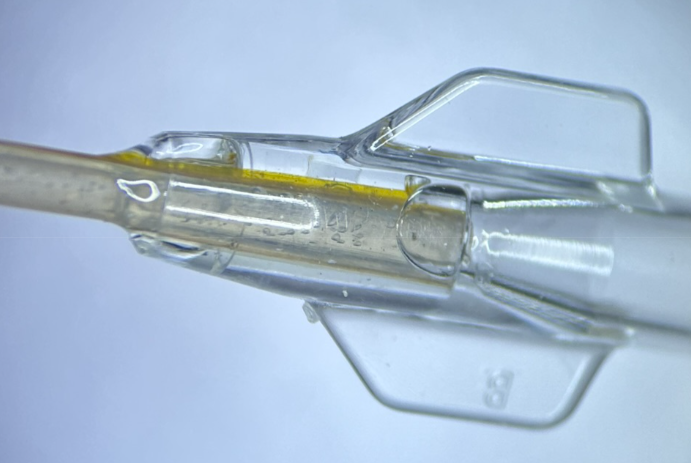

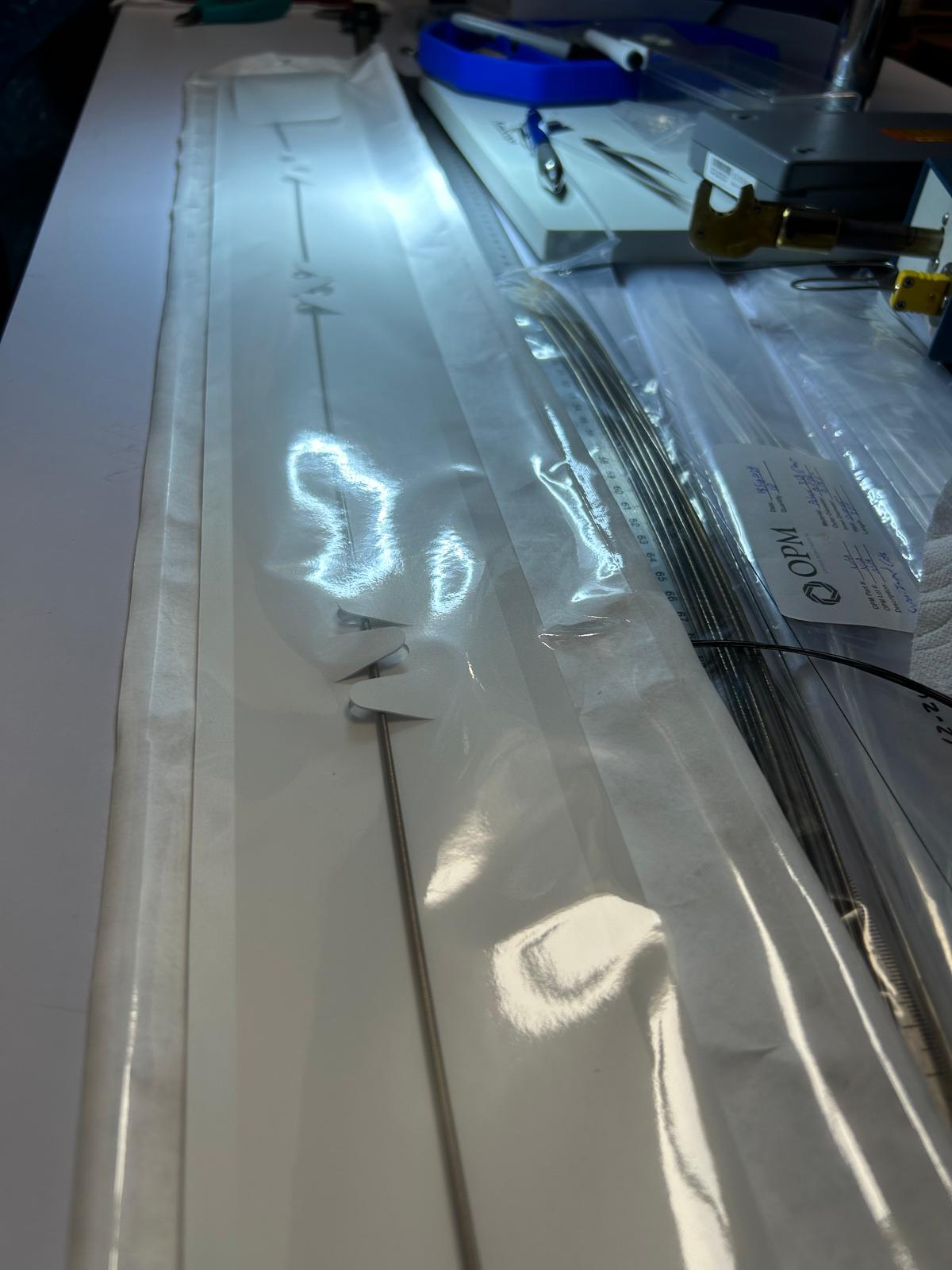

Catheter Lamination

Lamination or reflow is the process by a catheter shaft is formed by melting polymer jackets, reinforcing elements (braid, coil, laser-cut hypotube), and liners into a single composite structure.

Catheter Finishing

Catheters often require a fine finishing touch to terminate braid, join components, or touch up the tip. We have the skills and experience to complete this processing.

Tip Shaping

With the ability to cut tooling in-house, we can quickly achieve your desired tip shaping, iterating quickly to achieve any shape.

Radiopaque Marker Bands

We have a variety of techniques to add marker bands to a catheter, including swaging for longer-term production and split band for prototyping. Radiopaque polymers such as Barium Sulfate (BaSO4) or tungsten may also be added to polymers to create a radiopaque element.

Medical Balloon Forming

With our Interface Balloon Former, we focus on stretch blow molding of compliant balloons from materials such as flexible polyurethanes. In-house balloon mold design and fabrication speeds up time to First Articles and ensures quick iteration.

Adhesives

We utilized UV cure adhesives, cyanoacrylates, and epoxies to produce consistent and quality bonds. This includes bonds to luer hubs and other accessories.

Packaging and Labeling

Need a finished assembly? We have experience sourcing HDPE backer cards, Tyvek / poly pouches, PETG trays, shelf cartons, shippers, and more. We can also design custom labeling for your product, including pouch / carton labels and (if desired) IFU development.